Tyne Hanft-Kemp

she/her

Spinning - Knitting

Viola, WI

Instagram: @LouisaGaugeKnits

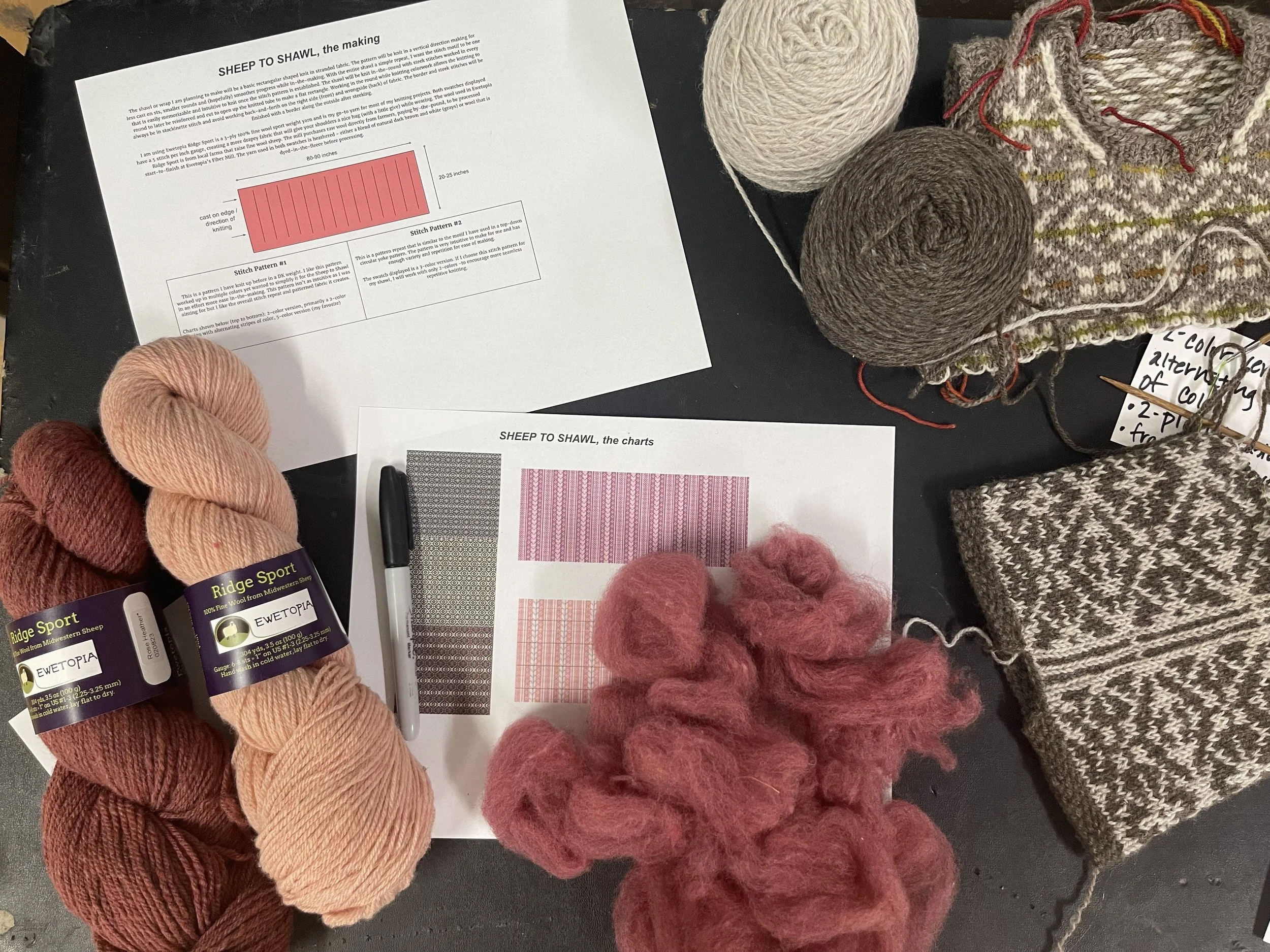

From Sheep to Shawl Project

I will be making a knitted steeked, stranded rectangular shawl made with 3-ply sport weight fine wool yarn sourced from local farms and made at Ewetopia Fiber Mill. This yarn is purchased (payment to farmer per pound), skirted, scoured, dyed and processed start-to-finish in our local mill. The purchasing of the wool from local farms keeps our local sheep and their shepherds employed and (we hope) promotes continual fine wool production in our small midwestern region.

The pattern will be self-designed by Louisa Gauge.

I am a custom knitter and designer, yarn maker at Ewetopia Fiber Mill, amateur shearer, shepherd and working dog enthusiast. Knitting began as a hobby for me in 2011 and has since become a drive for self-reliance within wool production. I started my custom knitwear and design business, Louisa Gauge, by turning commissioned designs into written patterns for purchase. The knit samples are often made with yarn milled at Ewetopia. My privilege of managing and shearing sheep for wool production makes the yarn I make and use even more valuable.

My goal as a shepherd is to be a steward to both the land and the sheep under my management. My goal as a yarn maker is to produce a consistent product that can be turned into a durable and well-worn garment. My goal as a maker is to create knit pieces and written patterns that are inclusive in size to many body types and tailored to be worn comfortably to the wearer for many years. To me, the fiber mill is the midpoint where the gritty raw wool becomes an item to be displayed in a local yarn store. It is an honor to have such a perspective and feel being a TRF Maker is a great way to showcase the hoof to garment transformation to connect the farmers, the fiber mills, the shearers, the makers, etc. who all have a contribution within the wool industry.

the project

the fiber

Sourced From - Ewetopia Fiber Mill - La Farge, WI

The purchasing of the wool from local farms keeps our local sheep and their shepherds employed and (we hope) promotes continual fine wool production in our small midwestern region.

Processing

This yarn is purchased (payment to farmer per pound), skirted, scoured, dyed and processed start-to-finish in our local mill, Ewetopia Fiber Mill.

The yarn is a 3-ply sport weight fine wool yarn.

Roving

Dyed wool

Roving being spun into yarn at Ewetopia Fiber Mill

Roving being spun into yarn

The Pattern

“Hearth Wrap” by Louisa Gage

This pattern was self-designed and will be will be released by Louisa Gauge within the next year. It is a stranded rectangular shawl with a garter stitch border. The motif was knit horizontally with the shawl sides steeked then finished with a knit border on all sides.

Tyne originally created this motif for a child's vest then adapted it to the wrap. The construction of the wrap is fairly straightforward with no shaping. The motif reminds me of stonework design on a warm and cozy hearth.

For the shawl, Tyne used a 3-ply fine wool spun at Ewetopia Fiber Mill. This insured regular yarn weight for stitch definition of the tedious colorwork and sticky fiber that would take to steeking well.

Finished yarn, roving, and pattern charts and samples

Hearth Wrap

Designed by Louisa Gage